The problem with hot dogs

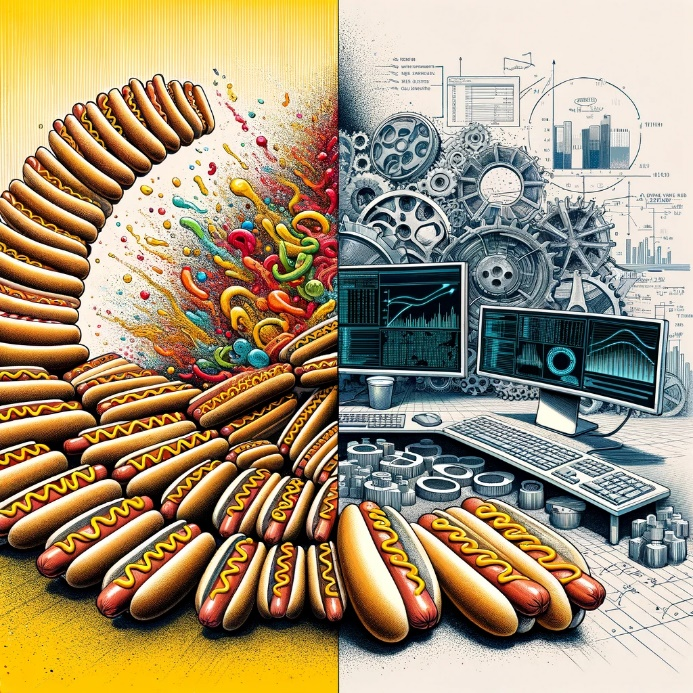

In 2001, a slender man named Takeru Kobayashi ascended the stage of Nathan’s Famous Fourth of July Hot Dog Eating Contest. He had traveled from Japan to New York’s Coney Island neighbourhood with a solid strategy that changed the annual competition forever. In his debut competition Kobayashi methodically munched 50 hot dogs in 12 minutes, doubling the contest’s previous record. However, this was more than a spectacle of consumption; it was the unveiling of a methodical approach that would redefine competitive eating. Kobayashi didn’t just eat; he solved a problem – how to eat as many hot dogs as possible in a limited time. And his approach to problem solving is more relevant to engineering design and modelling than appears on the surface.

Problem solving through iteration

The rules to Nathan’s Hot Dog Eating Contest are simple: eat as many hot dogs and buns as you can in 12 minutes (10 minutes as of 2008). You are allowed to drink anything you like, but you are not allowed to vomit significantly (which is known as a ‘reversal of fortune’ in the contest). Prior to Kobayashi’s debut, competitors ate the hot dogs in the conventional matter with the dog in the bun. Kobayashi identified the limitations to this convention and set out to find a faster method.

It must be said that his record smashing results in 2001 didn’t stem from a prodigious appetite but rather from a strategic and analytical approach to the problem. Simply put, he rigorously experimented and discovered increasingly faster ways to eat a hot dog in a step wise fashion. He tested and documented his progress through ideas such as breaking the hot dogs in half, eating the meat and bun separately, dipping the bun in water of varying water temperatures. Before stepping on the stage in 2001, Kobayashi had iterated this eating problem so many times that he had found a solution to eat more hot dogs in 12 minutes than many thought was humanly possible at that time. Since that paradigm shifting day in Coney Island, Kobayashi’s approach has been universally adopted in competitive eating with many competitors iterating further with their own methods. In the 30 years prior to Kobayashi, contestants ate about 15 dogs (the winning average) to be declared the winner. As of 2023, the Nathan’s record stands at 76 hot dogs in 10 minutes. Iterative problem solving has clearly had a significant impact on the rather unusual objective of eating a lot of hot dogs quickly.

How does this apply to engineering design?

From Eating Contests to Engineering Principles

Kobayashi’s method exemplifies the bottom-up approach to problem-solving. This method involves breaking down a complex task into its fundamental parts, understanding and optimizing each part, and then integrating these parts into an efficient whole. It’s a learn-by-doing and iterative process, and it’s a strategy that is successfully used in many fields, including engineering design.

The Bottom-Up Approach in Engineering

In engineering, the bottom-up approach is the default method of design whenever the system is too complex, not well constrained, or not fully understood. The bottom-up approach is exemplified through prototyping where the objective is to test and learn as much as possible about the system as quickly and as cheaply as possible. Wind tunnel tests, pilot studies, tank models, and mathematical models are all common tools employed in the bottom-up approach.

Advantages of the Bottom-Up Approach

• Discovering the important details: Particularly in complex systems, this approach allows engineers to study each component, leading to a better understanding of the system and distinguishing the relative importance of each.

• Innovation and Creativity: Through experimentation, engineers can test new ideas, discover new concepts, and explore innovative solutions based on patterns and hunches rather than first principles (which may be determined later).

• Fail when the stakes are low: Iterative testing allows the failure points to be revealed during prototyping. In this learn by doing method, each ‘failed’ prototype teaches you what does not work so that you can adjust accordingly for the next level prototype.

Prototyping for Groundwater Problems

Since the bottom-up approach works best on highly uncertain and complex systems, it is naturally suited to solving in groundwater problems. However, groundwater systems cannot be easily or cheaply experimented upon in the real world. As such the bottom-up approach for groundwater problems almost always involves prototyping through mathematical models.

The toolbox of mathematical models for prototyping in groundwater systems is large. It includes a spectrum of methods ranging from descriptive to predictive models. This is fortunate as it allows you to consider the problem from many different perspectives. With the bottom-up approach, the best mathematical model to choose is always the one that allows you to test and learn as much as possible about the system, as quickly and as cheaply as possible (and iterate as required). In practice, the bottom-up approach requires a modelling environment that is rapid and flexible. This approach can be applied to any problem, from a simple 1D hydrostatic model to a complex 3D flow model.

Unfortunately, many groundwater modelling projects are not set up to take advantage of the bottom-up approach. Instead, they tend to rely on a single complex mathematical version of the real world, which is difficult and expensive to design and often impossible to iterate with new concepts. These instances represent missed opportunities considering that a basic problem of faster eating, indelibly found a 3 to 5 times improvement through this bottom-up approach to problem solving.

Be more like Kobayashi

Takeru Kobayashi’s innovative strategy in competitive eating offers a valuable lesson for groundwater modeling. His application of the bottom-up approach, characterized by breaking down a complex task into simpler parts, and iteratively optimizing each element, mirrors the ideal strategy in engineering design for complex systems. This methodology promotes a thorough understanding of each component of a system, drives innovation, and mitigates risks by allowing failures in low-stake scenarios. While this approach is not yet universally applied in groundwater modeling, its potential for significant improvements is undeniable.